Finished the BAD add-ons, and am happy with the results.

Had a lot of mis-fires with this project. Started with 1/8" HDF from Home Depot, the stuff was a bear to drill, and in the end, couldn't handle the bend for the poly (started to crack down the center hole line). Was able to salvage a few pieces, to use as templates and for future flat panels.

Ended up recycling some manufactured solid poly panels I had bought a few years ago from an outfit out of Arkansas. I had used them with my Maggies, but didn't think they worked that well with the KEFs. They were up in the attic unused, already painted the room color and had a built in bend to them, ended up working perfectly.

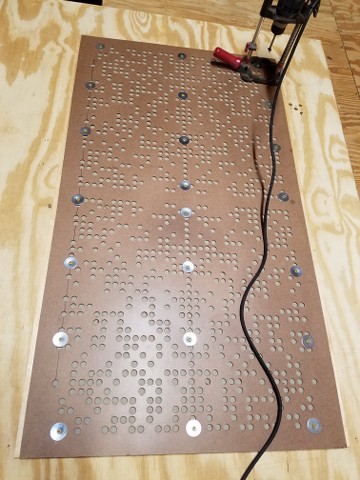

Here's one of the HDF panels that I used as a drilling template, screwed down on top of the other (birch?) poly panels, which in turn are on top of a sacrificial piece of plywood. I used a hand drill (using a 1/2" forstner drill bit) and hand drill press (all from Home Depot). The press is mainly used as a stop to control the drill depth. Took about 6-7 hours (not counting breaks) to do the holes.

The panels I mounted these to had 3/4" sidewall frame construction with aluminum angle added for support. Detailed in this thread:

http://www.audiocircle.com/index.php?topic=113202.0To catch and hold the sides of the curved panels, I mounted some of that aluminum channel that is used to hang bathroom mirrors on walls, to the existing panels. Added some nice metal cabinet shelf brackets on the bottom as a stop so the curved panels wouldn't slip down.

When I first tried these out, had them placed in the exact same location as the panel was as an absorber (centered to the mirror image of the speaker driver). Didn't sound all that great, lost some detail. Then I remembered reading an old Stereophile article about a particular curved diffuser being review, and how the reviewer ended up moving the panels a bit forward, so that the mirror image of the driver hit slightly pass the apex of the curve, closer to the listener. That did the trick. Got plenty of clear detail, but also new layers of depth. Pretty cool how a slight adjustment can make such a difference.

http://www.stereophile.com/content/acoustic-geometry-curve-system-room-treatments#Iq8UoUHwjucfG3Md.97Update: After more listening, I felt that even though the BADs on the sidewall expanded the soundstage (especially with out of phase material), it also damaged and confused the high end a bit. So I have moved them on to the rear wall corner bass traps, facing towards the front wall and out of the RFZ. So that will give me diffusion and bass trapping on the front and rear walls, and just absorption on the sidewalls.